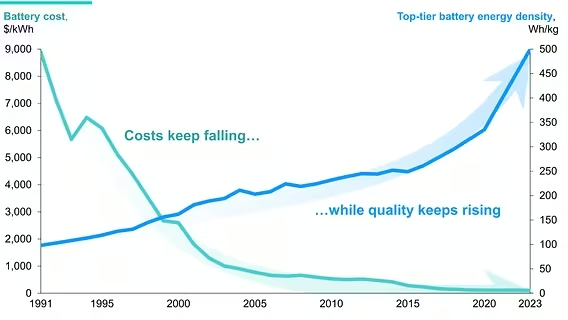

The transition toward a sustainable energy future has always been a race against the limitations of chemistry. For decades, the energy density of lithium-ion cells has seen incremental improvements, but 2025 has officially become the year of the breakthrough. As we close out this calendar year, the landscape of electric mobility and portable electronics has been fundamentally altered by a series of technical milestones that were once thought to be a decade away. From the commercialization of solid-state architectures to the widespread adoption of silicon-carbon anodes, the industry has finally broken the 400 Wh/kg barrier in production-ready formats.

- The Solid-State Revolution: Moving Beyond Prototyping

- Silicon-Carbon Anodes: The New Baseline for Portable Tech

- The Anode-Free Frontier: Records Shattered in South Korea

- CATL and the Diversification of Energy Storage

- Manufacturing Innovations: The Hidden Driver of Density

- Global Market Impact and Consumer Trends

- Looking Ahead: The Roadmap to 500 Wh/kg

- Summary of 2025 Battery Milestones

This evolution is not merely academic. It represents a tangible shift in how we interact with technology. Whether it is a smartphone that lasts three days on a single charge or an electric vehicle that matches the range of a diesel sedan, the improvements in energy density this year have solved the most significant bottleneck in the green energy transition. This article explores the specific innovations, the companies leading the charge, and the scientific breakthroughs that have defined this extraordinary year.

The Solid-State Revolution: Moving Beyond Prototyping

For years, solid-state batteries were considered the holy grail of energy storage. The promise was simple: replace the flammable liquid electrolyte with a solid ceramic or polymer material to increase safety and energy density simultaneously. In 2025, this promise transitioned into a reality on public roads.

One of the most significant moments of the year occurred in February 2025, when Mercedes-Benz, in partnership with Factorial Energy, successfully integrated a lithium-metal solid-state battery into a production vehicle platform. This was not a laboratory experiment but a functional integration into the Mercedes-Benz EQS. The results were staggering. The prototype achieved a 25 percent increase in driving range compared to the standard model, pushing the total estimated range to 620 miles. The energy density of these cells reached 375 Wh/kg, setting a new benchmark for high-performance luxury vehicles.

Toyota has also made massive strides this year. While the company has set its sights on mass production for 2027, its 2025 technical workshops revealed that it has finally overcome the long-standing issue of electrolyte durability. By developing a new solid electrolyte that is less prone to cracking during high-speed charging, Toyota has paved the way for batteries that can charge from 10 to 80 percent in under 10 minutes. These advancements are critical for reducing the physical footprint of the battery pack, allowing for lighter, more aerodynamic vehicle designs that do not sacrifice range.

Silicon-Carbon Anodes: The New Baseline for Portable Tech

While solid-state technology dominates the headlines for vehicles, silicon-carbon (Si-C) technology has quietly revolutionized the consumer electronics market in 2025. Traditionally, battery anodes were made of graphite. However, silicon has a theoretical capacity for lithium ions that is nearly ten times higher than that of graphite. The challenge has always been the physical expansion of silicon, which can swell by 300 percent during charging, leading to cell failure.

In 2025, a wave of smartphone manufacturers began systematically adopting Si-C cells. By incorporating silicon into a sophisticated carbon matrix, engineers have managed to control the expansion while harvesting the density benefits. This shift allowed flagship smartphones released this year to feature 6,000 mAh capacities in frames previously limited to 5,000 mAh.

In the automotive sector, US-based material science companies have introduced flexible silicon battery materials that boost EV range by up to 45 percent. These silicon anodes are now reaching energy densities of 400 Wh/kg in commercial samples. Companies like Group14 and Sionic Energy have reported that their silicon-rich materials are “market-ready,” offering over 1,200 charge cycles, which satisfies the longevity requirements for modern transportation.

The Anode-Free Frontier: Records Shattered in South Korea

If 2025 had to be defined by a single scientific record, it would be the development of the anode-free lithium-metal battery. Researchers from POSTECH, KAIST, and Gyeongsang National University in South Korea announced a major milestone in late 2025. They developed a battery that eliminates the traditional graphite anode entirely. Instead, lithium ions deposit directly onto a copper current collector during the charging process.

The volumetric energy density of this prototype reached 1,270 Wh/L. To put that in perspective, current high-end lithium-ion batteries typically hover around 650 to 700 Wh/L. By effectively doubling the volumetric density, this technology allows for a battery pack half the size of current models while maintaining the same range. To solve the problem of lithium dendrites (sharp needles that can cause short circuits), the team used a polymer structure embedded with silver nanoparticles. This “reversible storage framework” ensures that lithium deposits evenly, maintaining stability over hundreds of cycles.

CATL and the Diversification of Energy Storage

CATL, the global leader in battery manufacturing, spent 2025 proving that energy density improvements are not just for high-end lithium-metal cells. The company officially launched its Naxtra sodium-ion battery in December 2025. While sodium-ion is naturally less dense than lithium, CATL pushed its Naxtra passenger EV battery to 175 Wh/kg. This is comparable to traditional LFP (Lithium Iron Phosphate) batteries, but at a significantly lower cost and with better performance in extreme cold.

Furthermore, CATL unveiled its “self-forming anode technology” this year. This disruptive breakthrough at the atomic level allows for a 60 percent increase in volumetric energy density. When combined with Nickel Manganese Cobalt (NCM) chemistries, it can push energy density toward the 1,000 Wh/L mark. This innovation is a key reason why electric sedans with a 1,500-kilometer range are now being discussed as a feasible reality for the 2026-2027 model years.

Manufacturing Innovations: The Hidden Driver of Density

The improvements in 2025 are as much about how batteries are made as they are about what they are made of. Dry electrode manufacturing has moved from the pilot stage to the production stage. By eliminating the need for massive drying ovens and toxic solvents, manufacturers can create thicker electrodes with higher active material loading, which directly contributes to higher gravimetric energy density.

QuantumScape has been a central player in this manufacturing evolution. In December 2025, the company announced it had met its commercial engagement goals, signing a joint development agreement with a top-ten global automaker. Their focus has shifted to high-volume ceramic separator production in partnership with Murata and Corning. This industrialization of solid-state components is what will allow these high-density cells to move from limited luxury runs to the mass market.

Global Market Impact and Consumer Trends

The impact of these technological leaps is reflected in the 2025 market data. In Europe, EV penetration reached 29 percent by the end of the year, driven largely by the reduction in “range anxiety” made possible by these density gains. The average energy density of a new EV battery pack in 2025 is approximately 15 percent higher than it was in 2023, while costs have continued to stabilize due to the maturation of sodium-ion and LFP production lines in places like Indonesia and Spain.

For the average consumer, this means that the “standard range” for an entry-level vehicle has shifted from 250 miles to nearly 350 miles. In the world of aviation, the 400 Wh/kg and 500 Wh/kg prototypes seen this year have finally made short-haul electric flight (eVTOL) a commercially viable prospect. CATL’s two-ton eVTOL, for instance, has completed multiple flight validations using these advanced cells.

Looking Ahead: The Roadmap to 500 Wh/kg

As we move into 2026, the trajectory is clear. The focus is shifting toward lithium-sulfur batteries and the refinement of solid-state manufacturing. Lithium-sulfur holds the theoretical potential to reach 500 Wh/kg, though it still faces hurdles regarding cycle life. However, given the pace of innovation witnessed in 2025, few are betting against a solution appearing soon.

The integration of artificial intelligence in materials science has accelerated this process. AI models are now used to simulate millions of electrolyte combinations, a process that used to take years in a physical lab. This digital acceleration is the reason why breakthroughs that used to happen once a decade are now occurring almost monthly.

Summary of 2025 Battery Milestones

- Mercedes-Benz EQS: First production-platform integration of solid-state cells (375 Wh/kg).

- Anode-Free Breakthrough: South Korean researchers achieve a record 1,270 Wh/L volumetric density.

- CATL Naxtra: Mass production of 175 Wh/kg sodium-ion batteries begins.

- Silicon-Carbon Cells: Become the standard for flagship mobile devices, offering 20 percent more capacity.

- Toyota Solid-State: Breakthrough in electrolyte durability allows for 10-minute ultra-fast charging.

The energy density improvements of 2025 have laid the groundwork for a world where energy storage is no longer a constraint. As these technologies scale, the cost of high-performance energy will continue to drop, making the transition to a carbon-neutral economy not just an environmental necessity, but an economic inevitability.