The automotive landscape is undergoing its most significant shift since the introduction of the assembly line. As we move through the final days of 2025, the narrative surrounding electric vehicles (EVs) has pivoted from high-end luxury to mainstream accessibility. This transition is not merely a result of better marketing or government mandates; it is the direct consequence of a collapse in battery production costs. Today, the lithium-ion battery pack, once the most expensive hurdle for any car manufacturer, has reached price points that many analysts thought were a decade away.

- The Milestone: Breaking the 100 Dollar Per Kilowatt-Hour Barrier

- Why Are Battery Costs Falling So Quickly?

- Raw Material Trends: A Mixed Bag in 2025

- Regional Price Disparities: China vs. The West

- The Impact on New Vehicle Prices: The 25,000 Dollar EV Arrives

- Beyond Lithium: Sodium-Ion and Solid-State Breakthroughs

- How Battery Health Impacts Resale Value

- Conclusion: A Tipping Point for Global Transportation

The Milestone: Breaking the 100 Dollar Per Kilowatt-Hour Barrier

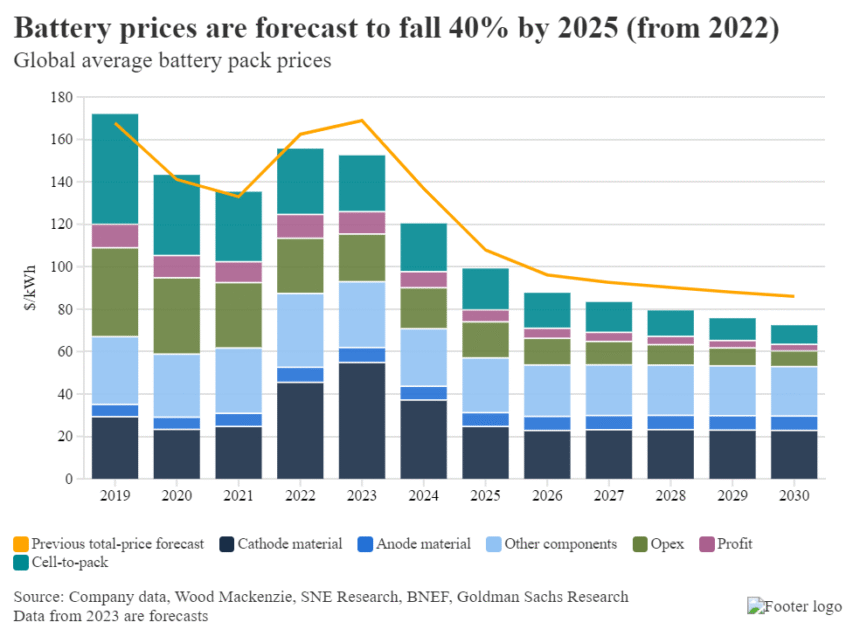

For years, the energy industry has pointed to $100 per kilowatt-hour (kWh) as the “magic number.” This is the threshold where electric vehicles achieve price parity with traditional internal combustion engine (ICE) vehicles without the need for government subsidies. According to the latest data from BloombergNEF’s 2025 Battery Price Survey, the industry has not only met this goal but surpassed it in several sectors.

Currently, the global average price for lithium-ion battery packs has hit a record low of $108/kWh, an 8 percent drop year over year. More impressively, the transport sector specifically has seen battery-electric vehicle (BEV) packs fall to $99/kWh. This marks the second consecutive year that prices have remained below the triple-digit mark, fundamentally changing the profit margins for automakers and the sticker prices for consumers.

Source: BloombergNEF Battery Price Survey 2025

Why Are Battery Costs Falling So Quickly?

Several factors are converging to drive these prices down. While raw material costs have faced volatility, manufacturing efficiency and chemistry shifts have more than compensated for those fluctuations.

1. Massive Manufacturing Overcapacity

The world is currently in a state of battery overproduction, particularly in China. Production capacity has roughly doubled the actual global demand in 2025. This “supply glut” has forced manufacturers to compete aggressively on price to secure contracts with major automakers like Volkswagen, Ford, and Tesla.

2. The Dominance of Lithium Iron Phosphate (LFP)

One of the biggest stories of 2025 is the widespread adoption of LFP chemistry. Unlike traditional Nickel Manganese Cobalt (NMC) batteries, LFP cells do not require expensive cobalt or nickel. They are safer, longer-lasting, and, most importantly, significantly cheaper. LFP battery packs currently average around $81/kWh, while NMC packs still hover near $128/kWh. As Western automakers finally integrate LFP into their entry-level models, the savings are being passed directly to the buyer.

3. Innovative Packaging: Cell-to-Pack (CTP) Technology

Manufacturers are moving away from complex modules. New designs like “Cell-to-Pack” and “Cell-to-Chassis” eliminate the need for extra housing and wiring within the battery pack. This reduces the weight of the vehicle and cuts manufacturing costs by nearly 15 percent.

Raw Material Trends: A Mixed Bag in 2025

While the overall cost of the battery pack is down, the raw materials themselves have told a different story this year. Understanding these trends is crucial for anyone tracking the long-term sustainability of EV price reductions.

Lithium and Graphite Oversupply

Lithium prices have remained under significant pressure throughout 2025 due to a surplus of supply from emerging mines in Argentina and Zimbabwe. This oversupply has kept lithium carbonate prices well below the peaks seen in 2022, providing a massive tailwind for battery manufacturers.

The Cobalt Embargo and Market Resilience

In a surprising turn of events earlier this year, the Democratic Republic of Congo (DRC) imposed export restrictions on cobalt to protect its market value. This caused a 40 percent spike in cobalt prices on the London Metal Exchange. However, because the industry has spent the last five years engineering “low-cobalt” or “cobalt-free” (LFP) batteries, the impact on final EV prices was surprisingly minimal. The market’s ability to “shrug off” a cobalt crisis is a testament to the technological flexibility of modern battery design.

Source: International Energy Agency Global EV Outlook 2025

Regional Price Disparities: China vs. The West

It is important to note that the $99/kWh average is not uniform across the globe. There is a stark contrast in EV affordability depending on where you live.

- China: As the global leader in battery refining and manufacturing, China sees the lowest prices. The average pack price in China is roughly $84/kWh. In this market, price parity with gas cars is already a reality across almost all vehicle segments.

- North America and Europe: Prices in these regions are significantly higher, often between 44 percent and 56 percent more expensive than in China. This is due to higher local labor costs, reliance on imported materials, and new trade tariffs designed to protect domestic industries. However, the gap is narrowing as “Gigafactories” in North America begin to scale up production.

The Impact on New Vehicle Prices: The 25,000 Dollar EV Arrives

The most exciting result of these cost reductions is the birth of the “Affordable EV.” For years, the $25,000 price point was considered the “Holy Grail” of electric transport. In 2025, we are finally seeing these vehicles hit the showroom floors.

Leading the Charge in Affordability

- Volkswagen ID.2: Aimed squarely at the European market, this model is designed to start at approximately 25,000 euros.

- Hyundai Inster: This compact EV is making waves with a budget-friendly price tag and a range that satisfies the needs of most urban commuters.

- Tesla’s Next-Gen Platform: While still in the early stages of wide-scale rollout, Tesla’s focus on “unboxed” manufacturing processes is expected to drive costs even lower for their future entry-level models.

Source: Electrek – New Entry-Level EV Market Trends

Beyond Lithium: Sodium-Ion and Solid-State Breakthroughs

While lithium-ion remains the king of the market, 2025 has been a pivotal year for “next-generation” chemistries.

Sodium-Ion: The Ultra-Budget Alternative

CATL, the world’s largest battery maker, recently confirmed that its sodium-ion batteries will see large-scale deployment starting in 2026. Sodium is abundant and incredibly cheap compared to lithium. While sodium-ion batteries have lower energy density (meaning less range), they are perfect for small urban cars and stationary energy storage. Analysts predict sodium-ion cells could eventually drop below $40/kWh.

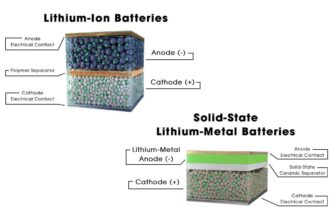

Solid-State: The 1,000 Kilometer Range

On the premium end, the race for solid-state batteries is heating up. Toyota has recently signaled that its first solid-state equipped vehicles could arrive as early as late 2026 or 2027. These batteries promise a range of over 1,200 km and a 10-minute charging time from 10 percent to 80 percent. While initially expensive, these batteries will eventually trickle down to more affordable segments, just as lithium-ion did.

How Battery Health Impacts Resale Value

As EVs become more common, the used car market is evolving. A major concern for buyers has been battery degradation: the fear that an older EV will have a “dead” battery that costs more than the car to replace.

Current data from 2025 suggests these fears were largely overstated. On average, EV batteries lose only about 2 percent of their capacity per year. A car purchased in 2018 is likely still retaining over 85 percent of its original range. Furthermore, new software diagnostics allow used car buyers to check the “State of Health” (SOH) of a battery before purchasing, similar to checking the mileage on a gas car. This transparency is stabilizing resale values and making “pre-owned” EVs a viable option for budget-conscious families.

Conclusion: A Tipping Point for Global Transportation

The year 2025 will be remembered as the moment the economic barriers to electric transportation finally crumbled. With battery pack prices dropping below $100/kWh, the argument for internal combustion engines is purely nostalgic rather than financial. As manufacturing efficiencies continue to improve and new chemistries like sodium-ion and solid-state come online, the cost of moving people and goods will continue to decline.

For the consumer, the message is clear: the electric vehicle is no longer a luxury for the few, but a practical, cost-effective tool for the many. The “EV revolution” has moved out of the laboratory and onto the driveway.