The global transition toward sustainable energy has reached a critical turning point as we close out 2025. For years, the primary barrier to widespread electric vehicle adoption and high performance consumer electronics was the limitations of energy storage. Specifically, the time required to refuel a vehicle compared to internal combustion engines has been a persistent hurdle. However, recent scientific milestones and industrial achievements have fundamentally altered the landscape of battery science.

- The Solid State Revolution: From Laboratory to Public Roads

- Molecular Engineering: The Mg4C60 Fullerene Breakthrough

- The Rise of Silicon Anodes: Breaking the 1000 Cycle Barrier

- Sodium Ion Technology: The Sustainable Alternative to Lithium

- Extreme Fast Charging (XFC) and Infrastructure Challenges

- Investment Trends and Market Dynamics in 2025

- The Environmental and Ethical Impact

- Conclusion and the Road to 2026

Today, we are witnessing a convergence of material science, nanotechnogy, and advanced manufacturing that is making the dream of a five minute charge a reality. From solid state electrolytes to revolutionary carbon frameworks, the innovations of late 2025 are setting the stage for a paradigm shift in how the world moves and stores power.

The Solid State Revolution: From Laboratory to Public Roads

The most significant development in the final quarter of 2025 has been the successful transition of solid state batteries from controlled laboratory environments to real world road testing. For decades, solid state technology was considered the holy grail of energy storage. By replacing the flammable liquid electrolyte found in traditional lithium ion cells with a solid ceramic or polymer material, researchers aimed to achieve higher energy density and unparalleled safety.

In late December 2025, Mercedes-Benz, in collaboration with Factorial Energy, made headlines by completing extensive road tests of a modified EQS sedan equipped with a lithium metal solid state battery. This vehicle demonstrated a range exceeding 745 miles (approximately 1,200 kilometers) on a single charge. What makes this achievement particularly noteworthy is not just the distance, but the stability of the battery under varied temperature conditions.

Factorial Energy, which recently announced plans to go public through a billion dollar merger, has utilized 106 Ah cells that significantly reduce the weight of the battery pack while increasing energy capacity. This development is expected to influence the high performance luxury market as early as 2027, with brands like Dodge and Jeep already verifying similar cells for their upcoming lineups.

Why Solid State Electrolytes Change Everything

Traditional batteries rely on a liquid medium for ions to travel between the anode and cathode. While effective, this liquid is volatile and limits how fast a battery can be charged without risking thermal runaway. Solid state electrolytes eliminate this risk, allowing for much higher current densities. This means chargers can pump energy into the battery at rates that would typically cause a standard battery to overheat or catch fire.

Moreover, the absence of liquid components allows for a more compact design. Researchers at imec recently announced a breakthrough in lithium metal solid state technology achieving an energy density of 1070 watt hours per liter. This is a massive leap from the 800 watt hours per liter seen in the best lithium ion cells of 2024.

Molecular Engineering: The Mg4C60 Fullerene Breakthrough

On December 27, 2025, researchers at Tohoku University published a landmark study in the Journal of the American Chemical Society regarding a new carbon based material. By redesigning how fullerene molecules are connected, the team created a covalently bridged framework known as Mg4C60.

This discovery addresses one of the most persistent problems in fast charging: structural degradation. When a battery is charged rapidly, the physical stress of lithium ions moving into the anode can cause materials like graphite to expand and eventually collapse. The Mg4C60 framework acts as a rigid, stable “skeleton” that can accommodate lithium ions at high speeds without losing its integrity.

The implications for this are twofold. First, it enables batteries to maintain a high power output over thousands of cycles. Second, it significantly reduces the risk of lithium plating, a phenomenon where lithium forms metallic “dendrites” that can short circuit the battery. By using this redesigned carbon material, manufacturers can offer fast charging capabilities that do not compromise the long term health of the battery.

The Rise of Silicon Anodes: Breaking the 1000 Cycle Barrier

While graphite has been the industry standard for anodes since the 1980s, silicon has long been recognized as a superior alternative due to its ability to hold ten times more lithium ions. The problem, however, has always been expansion. Silicon expands by up to 300 percent during charging, which typically leads to the anode shattering after only a few dozen uses.

In 2025, companies like Sila Nanotechnologies and Group14 Technologies have successfully commercialized silicon carbon composites and innovative binders that “cage” the silicon particles. These technologies allow for the high capacity of silicon while managing the physical swelling.

Recent reports indicate that these silicon enhanced batteries are now reaching cycle lives in excess of 1,000 cycles, making them viable for the mass market. By replacing just a fraction of the graphite in an anode with these silicon structures, energy density can be improved by 20 to 40 percent. More importantly, silicon anodes exhibit much lower internal resistance, which is a key requirement for extreme fast charging protocols.

Sodium Ion Technology: The Sustainable Alternative to Lithium

While high performance EVs focus on solid state and silicon, the mid range and budget sectors are looking toward sodium. In late December 2025, CATL, the world’s largest battery manufacturer, announced a massive strategic shift titled the “Dual Star” era. This strategy involves the parallel development of lithium ion and sodium ion batteries to mitigate the rising costs of lithium carbonate, which saw a 50 percent price increase in late 2025.

Sodium ion batteries, such as those under CATL’s Naxtra brand, offer several distinct advantages:

- Resource Abundance: Sodium is found in common salt, making it significantly cheaper and more geographically accessible than lithium.

- Temperature Resilience: These batteries can operate in temperatures as low as -40 degrees Celsius, solving a major pain point for EV owners in cold climates.

- Fast Charging Capability: Sodium ions move through the electrolyte more freely than lithium ions in certain conditions, allowing for a 15 minute charge to 80 percent capacity.

CATL expects that by 2026, sodium ion batteries will be used in passenger vehicles with ranges up to 500 kilometers. This transition is crucial for the democratization of electric mobility, ensuring that fast charging technology is not limited to luxury vehicles.

Extreme Fast Charging (XFC) and Infrastructure Challenges

Technological breakthroughs in the cell are only half of the equation. To achieve the 10 minute charge for 400 kilometers of range, the charging infrastructure must also evolve. This year has seen the deployment of next generation 400kW and 500kW charging stations across Europe and China.

The primary challenge at these power levels is heat. Both the charging cable and the battery itself must be actively cooled. New liquid cooled charging connectors and advanced Battery Management Systems (BMS) are now using artificial intelligence to predict thermal spikes before they occur. By adjusting the charging curve in real time based on the battery’s internal chemistry and ambient temperature, these systems can maximize speed while ensuring safety.

Investment Trends and Market Dynamics in 2025

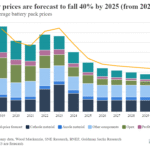

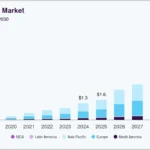

The financial landscape surrounding battery technology has reached a fever pitch in late 2025. The silicon anode battery market alone is projected to grow at a compound annual growth rate of 45 percent through 2032. Investors are increasingly moving away from companies that focus solely on traditional lithium ion and are instead backing startups involved in material science and solid state integration.

The recent $1.1 billion valuation of Factorial Energy and the surge in private equity for defense and aerospace battery applications highlight the strategic importance of this sector. Governments are also intervening with billions in subsidies for local battery manufacturing to reduce reliance on international supply chains, particularly for raw materials like graphite and cobalt.

The Environmental and Ethical Impact

Beyond performance, the breakthroughs of 2025 are also addressing the environmental concerns of battery production. The shift toward lithium sulfur and sodium ion chemistries reduces the need for cobalt and nickel, minerals often associated with high environmental and human costs in mining.

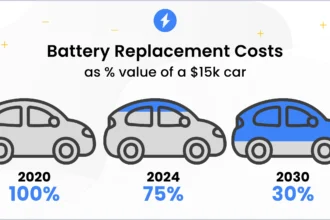

Furthermore, the increased longevity provided by materials like Mg4C60 and silicon composites means that batteries will last the entire life of a vehicle, or even be repurposed for grid storage after their automotive use. This “second life” for batteries is a core component of the circular economy models being adopted by major automakers.

Conclusion and the Road to 2026

The year 2025 will be remembered as the moment the technical barriers to electric transportation began to crumble. The combination of solid state stability, fullerene structural engineering, and the cost effectiveness of sodium ion technology has created a diverse ecosystem of energy storage solutions.

As we look toward 2026, the focus will shift from “can we do it” to “how fast can we scale it.” The road testing of solid state vehicles is only the beginning. With manufacturing partnerships like the one between Quintus Technologies and Lyric Robot looking to industrialize solid state production, the five minute charge is no longer a distant vision but an imminent reality.