The year 2026 marks a pivotal era for the automotive industry. It is the year when the promise of long range, ultra fast charging, and price parity with internal combustion engines finally moves from the laboratory to the driveway. If you are looking at an electric vehicle today, you are looking at a machine powered by chemistries and engineering breakthroughs that were considered experimental just a few years ago. Understanding how these batteries work is essential for anyone interested in the future of transport, sustainable energy, and high performance engineering.

- The Core Fundamentals of Modern Battery Architecture

- The Solid State Revolution: Beyond Liquid Electrolytes

- Sodium Ion Batteries: Making EVs Affordable

- Dry Electrode Manufacturing: A Greener Production Process

- The Intelligence of the Pack: AI Driven Battery Management

- Charging Infrastructure and 800V Architectures

- Structural Batteries: The Car is the Battery

- Thermal Management and Heat Pumps

- The Circular Economy: Recycling and Second Life

- Geopolitics and the Supply Chain of 2026

- Market Outlook: The Tipping Point of 2026

The Core Fundamentals of Modern Battery Architecture

To understand the 2026 electric vehicle battery, one must first look at the basic building blocks that have evolved. Every battery pack in a modern vehicle consists of thousands of individual cells organized into modules, which are then integrated into a single massive pack. These packs are usually located at the base of the vehicle to lower the center of gravity.

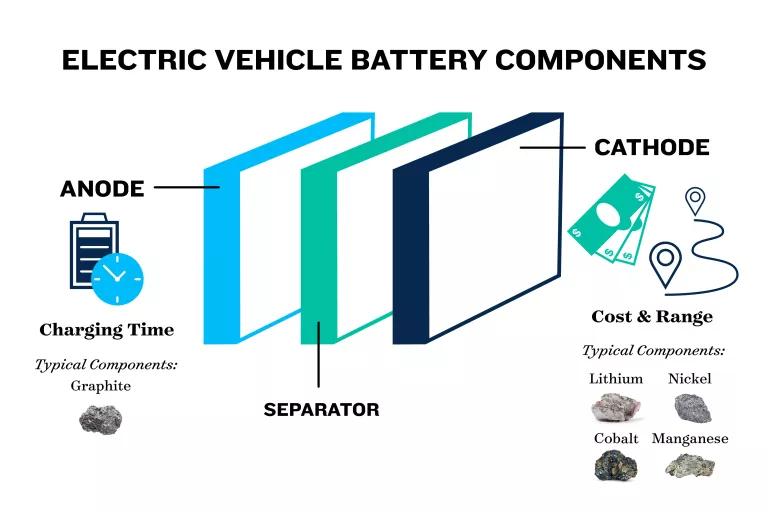

In 2026, the movement of ions remains the primary method of storing and releasing energy. When you charge your car, lithium ions move from the positive cathode to the negative anode through a substance called the electrolyte. When you drive, this process reverses, creating a flow of electrons that powers the electric motors. However, the materials and the efficiency of this movement have changed drastically.

The Cathode: The Power Center

The cathode is the most expensive and critical part of the battery. In 2026, we see a divergence in cathode technology. High performance vehicles typically use Nickel Manganese Cobalt (NMC) or Nickel Cobalt Aluminum (NCA) chemistries. These materials allow for high energy density, which translates to longer range. Engineers have worked tirelessly to reduce cobalt content because it is expensive and difficult to source. Modern cathodes now use high nickel formulations, often reaching 80 percent or 90 percent nickel content, to squeeze every possible kilowatt hour out of the pack.

The Anode: Silicon and Lithium Metal

The anode has seen the most significant material shift in recent years. Traditionally made of graphite, the 2026 anode often incorporates silicon or even pure lithium metal. Silicon is capable of holding significantly more lithium ions than graphite, but it has a tendency to expand and contract during use. Advanced nanostructures and specialized binders now manage this expansion, allowing for batteries that can charge much faster without damaging the internal structure.

The Solid State Revolution: Beyond Liquid Electrolytes

Perhaps the most significant development of 2026 is the commercialization of solid state batteries. For decades, the industry relied on liquid electrolytes to move ions. While effective, liquid electrolytes are flammable and sensitive to extreme temperatures.

How Solid State Works

Solid state batteries replace the liquid or gel electrolyte with a solid ceramic or polymer layer. This shift provides three major advantages:

- Safety: Because there is no flammable liquid, the risk of thermal runaway is almost entirely eliminated.

- Energy Density: Solid electrolytes are much thinner, allowing more active material to be packed into the same space.

- Longevity: These batteries suffer less degradation over thousands of charge cycles.

Companies like Toyota and QuantumScape have led the charge in this sector. In 2026, we are seeing the first production vehicles equipped with solid state technology. These cars can offer a range of over 500 miles on a single charge and can be replenished in less than fifteen minutes. This technology effectively removes the final barriers for many consumers who were previously worried about long distance travel.

Sodium Ion Batteries: Making EVs Affordable

While high end cars utilize solid state tech, the mass market has embraced sodium ion batteries. This is one of the most exciting trends of 2026 because it addresses the issue of cost. Sodium is abundant, cheap, and can be found almost anywhere in the world.

The Benefits of Sodium

Unlike lithium, which is subject to geopolitical supply chain risks, sodium is essentially salt. Sodium ion batteries are slightly less energy dense than lithium ion ones, making them slightly heavier for the same amount of power. However, they excel in other areas. They are much safer, they perform significantly better in cold weather, and they are roughly 30 percent cheaper to manufacture. For urban commuters and small city cars, sodium ion technology has become the standard in 2026.

Dry Electrode Manufacturing: A Greener Production Process

The way batteries are made is just as important as the materials inside them. In 2026, the shift to dry electrode coating has revolutionized the factory floor. Traditionally, battery electrodes were coated using a wet slurry that required massive ovens to dry. This process was energy intensive and required toxic solvents like NMP.

The dry electrode process, pioneered by companies like Tesla and refined by major suppliers like Panasonic, uses a dry powder and high pressure rollers to apply the material directly to the current collector. This reduces the energy consumption of the factory by nearly 50 percent and shrinks the footprint of the manufacturing facility. It also results in a more robust battery that is less prone to internal defects.

The Intelligence of the Pack: AI Driven Battery Management

In 2026, a battery is not just a chemical storage tank: it is a smart device. The Battery Management System (BMS) has been enhanced by artificial intelligence. This software acts as the brain of the battery, monitoring every cell in real time.

Predictive Maintenance and Health

AI algorithms can now predict when a cell might fail weeks before it actually does. By analyzing subtle fluctuations in voltage and temperature, the BMS can adjust the load to prevent damage. This has extended the average lifespan of an EV battery to over 300,000 miles, far outlasting the vehicle itself.

Edge Computing in EVs

Modern BMS units use edge computing to process data locally. This allows for instantaneous adjustments during fast charging. If the system detects a rise in heat, it can instantly modulate the cooling system or the incoming current to ensure the battery remains in its optimal “Goldilocks” temperature zone.

Charging Infrastructure and 800V Architectures

The year 2026 has seen the 800 volt (800V) electrical architecture become the standard for most mid range and luxury EVs. Moving from 400V to 800V allows for much higher charging speeds without increasing the thickness and weight of the wiring.

Ultra Fast Charging

With 800V systems, many 2026 vehicles can take advantage of 350kW or even 500kW chargers. This means adding 200 miles of range in roughly the time it takes to grab a cup of coffee. Furthermore, the 2026 charging experience is now unified. Most manufacturers have adopted the North American Charging Standard (NACS) or similar global protocols, ensuring that any car can use almost any charger without the need for cumbersome adapters.

Structural Batteries: The Car is the Battery

One of the most radical engineering shifts in 2026 is the rise of structural battery packs. In older EV designs, the battery was a separate component placed inside the chassis. In modern 2026 designs, the battery pack is a part of the vehicle structure itself.

By using the battery casing as a structural member of the car’s frame, engineers can eliminate hundreds of pounds of redundant metal. This makes the car lighter, which improves efficiency, and stiffer, which improves handling and safety. The “cell to pack” (CTP) and “cell to chassis” (CTC) designs are now the industry benchmark for efficiency.

Thermal Management and Heat Pumps

Battery performance is highly dependent on temperature. In 2026, thermal management systems have reached a level of extreme efficiency. Most modern EVs now use highly advanced heat pumps that can scavenge heat from the battery, the motors, and even the ambient air to warm the cabin.

This is crucial for winter performance. In previous years, EVs could lose up to 40 percent of their range in freezing temperatures because they used resistive heating. With the 2026 thermal management suites, that loss has been reduced to less than 15 percent. Preconditioning, where the car uses grid power to bring the battery to the perfect temperature before you even leave your driveway, is now a standard feature managed via smartphone apps.

The Circular Economy: Recycling and Second Life

Sustainability is the primary driver of the 2026 energy landscape. We have moved past the “take, make, waste” model. Battery recycling is now a profitable and highly efficient industry.

Direct Recycling

Instead of melting down batteries to extract raw elements, 2026 recycling facilities use direct recycling methods. This involves stripping the cathode material and refreshing it so it can be used in new batteries immediately. This process uses much less energy and recovers up to 98 percent of the critical minerals like lithium and nickel.

Second Life Applications

When a battery eventually degrades to about 70 percent of its original capacity, it is no longer ideal for a car, but it is perfect for stationary storage. These “second life” batteries are being used to power homes, stabilize the power grid, and store energy from solar farms. In 2026, retired EV batteries are a key component of the global renewable energy infrastructure.

Geopolitics and the Supply Chain of 2026

The supply chain for batteries has undergone a massive regionalization. In 2026, nations are competing to build “Gigafactories” within their own borders to reduce dependence on foreign imports. This “friend-shoring” has led to a boom in battery production in North America, Europe, and Southeast Asia.

New mining techniques, such as Direct Lithium Extraction (DLE), have made it possible to source lithium from geothermal brines with a much lower environmental impact than traditional open pit mines. This has addressed many of the ethical concerns that shadowed the industry in its early years.

Market Outlook: The Tipping Point of 2026

The most important takeaway for 2026 is that the cost of an electric vehicle battery has fallen below the critical $100 per kilowatt hour mark. This is the tipping point that experts have been waiting for. It means that, for the first time, an electric car is cheaper to build than a comparable gasoline car.

When you combine lower purchase prices with significantly lower fuel and maintenance costs, the economic argument for EVs becomes undeniable. The battery is no longer a luxury component: it is a commodity that is powering a global shift in how we move.