The automotive industry is currently navigating its most significant pivot since the invention of the internal combustion engine. As we reach the final days of 2025, the narrative around electric vehicles (EVs) is shifting from “when will they be ready?” to “how far can they go?” The limitations that once tethered electric mobility to urban environments—long charging times, range anxiety, and high costs—are being systematically dismantled by a wave of breakthrough battery chemistries. This transformation is not just evolutionary: it is a total reimagining of how energy is stored and deployed.

- The Solid State Breakthrough: Moving Beyond Liquid Electrolytes

- Sodium Ion Technology: The Key to Affordable Mass Market Mobility

- Silicon Anodes and the 10 Minute Charging Revolution

- Anode Free Lithium Metal: Doubling Energy Density

- Safety Standards and Regulatory Shifts: The 2026 Mandate

- The Sustainability Factor: Recycling and Circular Economy

- The Future of Charging Infrastructure: Wireless and AI-Driven

- Economic Implications for the Automotive Sector

- Conclusion: A Turning Point for Global Mobility

The Solid State Breakthrough: Moving Beyond Liquid Electrolytes

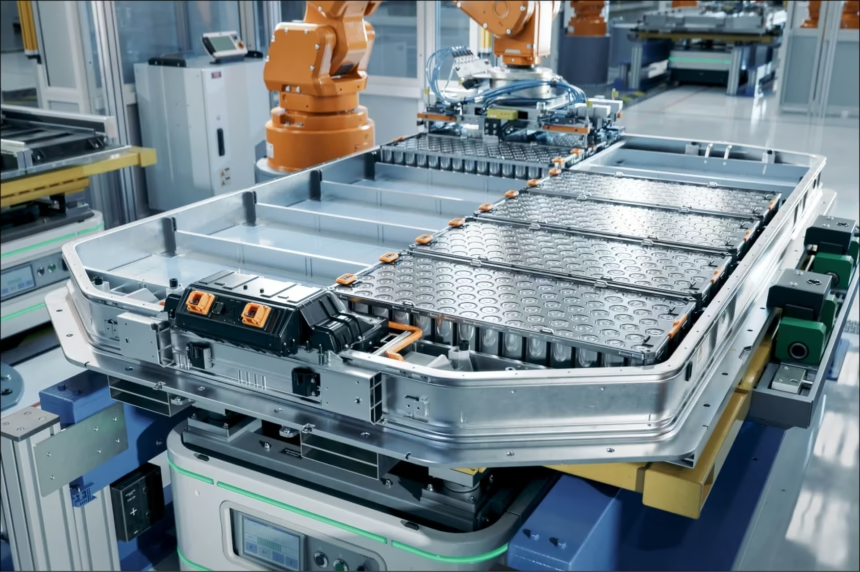

For decades, the lithium-ion battery has been the gold standard, but it is nearing its theoretical physical limits. The industry is now rapidly transitioning toward solid-state technology. Unlike traditional batteries that use a liquid electrolyte to move ions between the anode and cathode, solid-state batteries utilize a solid ceramic or polymer separator. This change addresses the two biggest hurdles in the sector: safety and energy density.

Just this week, reports have highlighted Toyota’s accelerated roadmap for its first solid-state powered vehicle. The Japanese automaker is targeting a staggering 1,200 kilometer range with a charge time of just 10 minutes. By replacing the flammable liquid electrolyte with a stable solid medium, these batteries virtually eliminate the risk of thermal runaway, a major concern for first-generation EV adopters.

Furthermore, companies like Factorial and QuantumScape are making significant strides in commercialization. Factorial recently announced it is moving toward public listing following a successful real-world test where its solid-state cells cleared 745 miles on a single charge. Meanwhile, QuantumScape has begun shipping its B1 samples, produced using their proprietary Cobra manufacturing process, to partners like the Volkswagen Group. These milestones indicate that the laboratory phase is over, and the industrialization of solid-state power is officially underway.

Sodium Ion Technology: The Key to Affordable Mass Market Mobility

While solid-state batteries target the high-performance and long-range segments, sodium-ion batteries are emerging as the champion of affordability. As of late December 2025, CATL has confirmed that its second-generation Naxtra sodium cells are entering mass production. With an energy density of 175Wh/kg, these cells are now on par with Lithium Iron Phosphate (LFP) batteries but offer several distinct advantages.

Sodium is abundant and significantly cheaper than lithium. This cost advantage is critical as the world seeks to produce budget-friendly EVs that can compete directly with gasoline-powered subcompacts. Sodium-ion batteries also perform exceptionally well in cold climates, maintaining high efficiency where traditional lithium-ion packs often struggle. This makes them a “game-changer” for Northern Europe, Canada, and the Midwestern United States.

Strategic partnerships are also fueling this niche. The recent collaboration between Sinopec Group and LG Chem to develop advanced anode and cathode materials for sodium-ion systems demonstrates a global commitment to diversifying energy sources. By reducing the reliance on scarce lithium, the industry is creating a more resilient supply chain that is less susceptible to geopolitical price fluctuations.

Silicon Anodes and the 10 Minute Charging Revolution

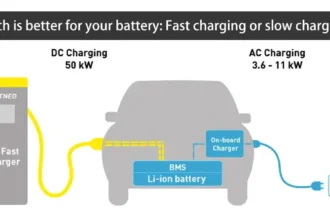

The quest for Extreme Fast Charging (XFC) has found a powerful ally in silicon-dominant anodes. Traditionally, anodes are made of graphite, but graphite has a limited capacity to host lithium ions. Silicon can hold significantly more, but it historically suffered from expansion issues that caused batteries to degrade quickly.

In 2025, StoreDot has successfully bypassed these limitations. Their silicon-based XFC batteries, which are now entering mass production, can restore 70 percent of a vehicle’s energy in just ten minutes without compromising the battery’s lifespan. Their recent “1 million kilometer” pack-level tests prove that silicon technology is ready for the rigors of daily driving.

By integrating silicon nanoparticles into the carbon electrode structure, manufacturers are achieving a 50 percent increase in energy density compared to conventional cells. This means smaller, lighter battery packs that do not sacrifice range, leading to more efficient vehicle designs and lower overall manufacturing costs.

Anode Free Lithium Metal: Doubling Energy Density

Perhaps the most radical development of the year comes from South Korea. Researchers at POSTECH and KAIST have unveiled a functional anode-free lithium metal battery with a volumetric energy density of 1,270 Wh/L. This is nearly double the capacity of the highest-performing lithium-ion batteries currently on the road.

The anode-free design works by allowing lithium ions to deposit directly onto a copper current collector during the charging process. By removing the traditional graphite or silicon anode entirely, the battery becomes lighter and more compact. The primary challenge has always been the formation of dendrites, which are needle-like structures that can cause short circuits. However, the introduction of a dual-solution storage framework and a specialized electrolyte has successfully mitigated this risk, paving the way for ultra-lightweight EVs and even electric aviation.

Safety Standards and Regulatory Shifts: The 2026 Mandate

Technology alone is not the only driver of change. Safety regulations are becoming increasingly stringent. China, the world’s largest EV market, recently finalized its GB 38031-2025 national standards. This mandate requires that all new EV power batteries must not catch fire or explode under any circumstances, marking the first time such a high safety threshold has been made a legal requirement.

This regulation is forcing automakers to optimize their thermal management systems and adopt inherently safer chemistries like semi-solid and all-solid-state cells. We are already seeing the fruits of this shift with the Dongfeng Nammi 01, the first mass-produced car featuring semi-solid battery technology. It offers a range of 530 kilometers and serves as a blueprint for the “safety-first” era of electric mobility.

The Sustainability Factor: Recycling and Circular Economy

As the volume of EVs on the road grows, the focus on the end-of-life cycle for batteries has intensified. The transition to a circular economy is now a central pillar of the automotive industry. New standards approved in late 2025 cover the recycling, dismantling, and regeneration of used power batteries.

Advancements in “Direct Recycling” allow for the recovery of cathode materials without the need for energy-intensive smelting. This not only reduces the environmental footprint of battery production but also provides a “secondary mine” of materials like cobalt, nickel, and lithium. By 2026, many regions will require a minimum percentage of recycled content in all new batteries, ensuring that the green revolution remains truly sustainable from cradle to grave.

The Future of Charging Infrastructure: Wireless and AI-Driven

The transformation of EVs is also changing the way we interact with the power grid. Charging is becoming a passive, intelligent experience. High-power wireless charging systems are now delivering up to 150 kW, allowing drivers to “fuel up” simply by parking over a pad.

Furthermore, AI-driven predictive charging algorithms are now standard in high-end 2026 models. These systems analyze driving patterns and weather conditions to precondition the battery for the fastest possible charge. When combined with vehicle-to-grid (V2G) technology, EVs are no longer just consumers of energy: they are mobile storage units that can stabilize the grid during peak demand.

Economic Implications for the Automotive Sector

The rapid advancement of battery tech is fundamentally altering the economics of car ownership. As energy density increases and production costs fall, the Total Cost of Ownership (TCO) for EVs is plummeting. Industry analysts project that the sodium-ion market alone will grow at a compound annual growth rate of nearly 20 percent over the next decade.

For consumers, this means that the premium price tag once associated with electric cars is vanishing. For manufacturers, the race is on to secure intellectual property and raw material pipelines. The shift toward silicon and solid-state tech is creating a new hierarchy of automotive leaders, where the most successful brands are those that act more like technology firms than traditional assembly-line manufacturers.

Conclusion: A Turning Point for Global Mobility

The battery breakthroughs of 2025 represent more than just technical achievements: they are the catalysts for a cleaner, faster, and more accessible future. From the 1,200 kilometer range promised by solid-state cells to the extreme fast charging of silicon anodes and the affordability of sodium-ion packs, the “perfect battery” is no longer a myth. It is a reality that is hitting the assembly lines today.

As we look toward 2026, the integration of these technologies will continue to accelerate, driving us toward a world where electric mobility is the default choice for every person on the planet. The age of energy limitation is over. The age of transformation has begun.

Sources and References for Further Reading

- Toyota Europe: Battery Technology Roadmap for the Future of Cars

- QuantumScape Investor Relations: Shipment of B1 Samples and Cobra Process Update

- VietNamNet Science & Tech: New Anode-Free Lithium Metal Battery Breakthrough

- CarNewsChina: Mandatory “No Fire” EV Battery Standards Finalized

- ResearchNester: Sodium-Ion Battery Market Outlook and Forecast 2035

- Persistence Market Research: Silicon Anode Battery Market Trends and Growth Analysis

https://kentshield.online/category/news/battery-technology-breakthroughs