The global energy landscape is undergoing a monumental shift as we enter 2026. For years, the promise of a battery that could charge as fast as a gas tank fills and last for over a thousand kilometers seemed like a distant dream. However, the latest breakthroughs in solid-state battery technology have officially moved from the laboratory to the production line. This article explores the current state of solid-state batteries in 2026, the key industry players driving this change, and why this technology is the most important development in the world of renewable energy and electric mobility.

- The Evolution of Battery Technology Toward 2026

- How Solid-State Batteries Work in 2026

- Key Performance Metrics for 2026

- Major Industry Players and Their 2026 Milestones

- The Global Impact on Electric Vehicles

- Industrial and Aviation Applications

- The Challenges of Scalability and Cost

- Sustainable Manufacturing and Recycling

- Investment Trends in Next-Gen Energy

- Daily Information and Real-Time Developments

- Conclusion and Future Outlook

- Sources for Further Reading

The Evolution of Battery Technology Toward 2026

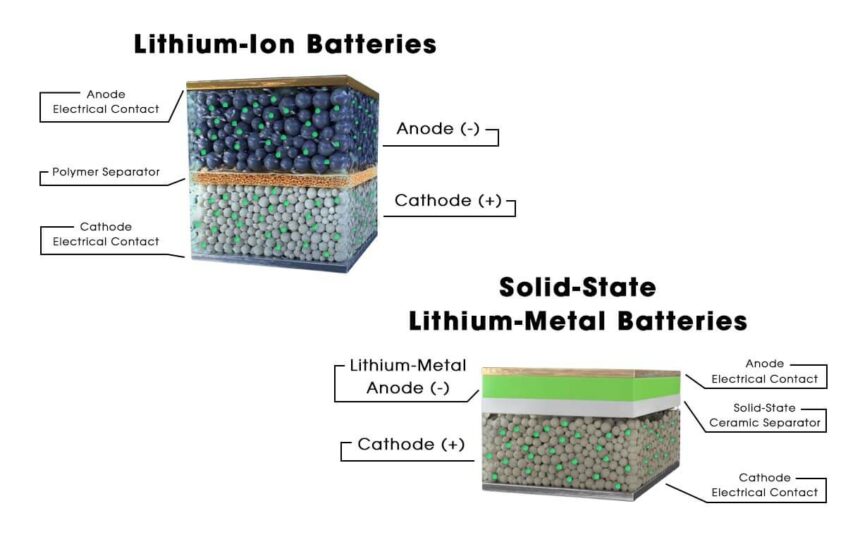

To understand why 2026 is such a pivotal year, one must look at the limitations of traditional energy storage. For over three decades, lithium-ion batteries have been the gold standard. They power our smartphones, laptops, and the first generation of electric vehicles. While effective, they rely on a liquid electrolyte to move ions between the anode and cathode. This liquid is flammable, sensitive to extreme temperatures, and limited in how much energy it can store.

Solid-state batteries change the fundamental architecture of the power cell. By replacing the liquid electrolyte with a solid material, such as ceramic, glass, or sulfide, manufacturers have unlocked a new dimension of performance. In early 2026, we are seeing the first real-world applications of these cells in high-end automotive and specialized industrial sectors. The shift is not just incremental. It is a total reimagining of how we store and deploy electrical energy.

How Solid-State Batteries Work in 2026

The core mechanism of a solid-state battery involves a solid electrolyte. In 2026, the industry has largely converged on three primary types of electrolytes: sulfides, oxides, and polymers. Sulfide-based electrolytes are currently the leaders in the automotive sector due to their high ionic conductivity, which allows for rapid charging.

One of the most significant technical achievements of the past year has been the successful management of lithium dendrites. In older designs, tiny needle-like structures called dendrites would grow through the electrolyte, causing short circuits. New ceramic separators developed by companies like QuantumScape and ProLogium have effectively neutralized this threat. These separators are dense enough to block dendrite growth while remaining thin enough to maintain high energy density.

Another breakthrough involves the anode. While traditional batteries use graphite or silicon-carbon anodes, the 2026 generation of solid-state cells is moving toward lithium-metal anodes. This allows for a much higher concentration of energy in a smaller footprint. By eliminating the need for bulky cooling systems and heavy casings required for liquid electrolytes, the entire battery pack becomes significantly lighter and more efficient.

Key Performance Metrics for 2026

The data coming out of pilot production plants in early 2026 is staggering. Here are the benchmarks that define the current generation of solid-state energy storage:

- Energy Density: Most leading cells now exceed 400 Wh/kg, with some experimental units reaching 500 Wh/kg. For comparison, traditional lithium-ion cells usually peak around 250 to 300 Wh/kg.

- Charging Speed: Solid-state cells can now achieve a 10 percent to 80 percent charge in under 10 minutes. This nearly matches the time spent at a traditional fueling station.

- Operating Temperature: These batteries remain stable and efficient at temperatures ranging from minus 30 degrees Celsius to over 100 degrees Celsius. This eliminates the “winter range loss” that has plagued electric vehicles for a decade.

- Cycle Life: Recent testing shows that high-quality solid-state cells can withstand over 1,500 full charge cycles with less than 10 percent degradation. This suggests a vehicle lifespan of over 800,000 kilometers.

Major Industry Players and Their 2026 Milestones

The race to dominate the solid-state market has created a new hierarchy of tech and automotive giants. In 2026, several companies have separated themselves from the pack.

Toyota and the Japanese Alliance

Toyota has long been a proponent of solid-state technology. In late 2025, the company received official production approval from the Japanese government for its sulfide-based cells. As we begin 2026, Toyota is scaling its pilot production lines in partnership with Idemitsu Kosan. Their goal is to integrate these batteries into the Lexus flagship line by 2027, with 2026 serving as the final year of rigorous on-road validation. Toyota’s roadmap suggests a range of 1,200 kilometers per charge, a figure that was unthinkable just a few years ago.

QuantumScape and the Cobra Process

Based in the United States, QuantumScape has made massive strides with its proprietary Cobra manufacturing process. In early 2026, the company has begun delivering B-samples of its QSE-5 cells to major automotive partners, most notably the Volkswagen Group. The Cobra process is a high-speed, continuous manufacturing method that solves the scalability issues that previously hindered solid-state production. By moving from batch processing to a continuous flow, QuantumScape has significantly reduced the cost per kilowatt-hour.

Samsung SDI and the 900Wh/L Threshold

Samsung SDI has focused on volumetric energy density. Their 2026 pilot line is producing cells that reach 900 watt-hours per liter. This focus on “small and powerful” makes their technology highly attractive not only for cars but also for the premium consumer electronics market. Samsung is currently shipping samples to global automakers for integration into high-performance sports cars where weight and space are at a premium.

The Rise of Chinese Manufacturers

Chinese firms such as CATL, NIO, and GAC Group are pursuing a two-track strategy. While they continue to dominate the traditional lithium-ion market, they have aggressively moved into semi-solid and all-solid-state designs. NIO’s 150 kWh semi-solid pack is already in use through its battery-swap network, providing a practical bridge to the all-solid-state future. GAC Group has recently announced its own all-solid-state line, aiming for mass deployment in its premium Haot Platinum models by the end of 2026.

The Global Impact on Electric Vehicles

The integration of solid-state batteries in 2026 is fundamentally changing the consumer’s perception of electric vehicles. The “range anxiety” that once served as a barrier to adoption is rapidly evaporating. When a vehicle can travel 1,000 kilometers on a single charge, it exceeds the range of most internal combustion engines.

Furthermore, the safety profile of these vehicles has improved dramatically. Because the solid electrolyte is non-flammable, the risk of thermal runaway is virtually eliminated. This has led to a decrease in insurance premiums for next-generation electric cars and has simplified the design of charging infrastructure.

Industrial and Aviation Applications

While cars get most of the headlines, 2026 is also seeing solid-state technology take flight. The aviation industry has been searching for a battery with the energy density required for regional electric flight. Traditional batteries are simply too heavy. The 450 Wh/kg threshold reached by solid-state cells in 2026 has made short-haul electric planes viable for the first time. Companies are currently testing 19-seat commuter planes powered entirely by solid-state packs.

In the industrial sector, large-scale energy storage systems are adopting solid-state technology for its longevity and safety. Grid-scale storage is essential for balancing renewable energy sources like wind and solar. The ability of solid-state batteries to operate without complex cooling systems makes them ideal for remote or harsh environments, such as desert solar farms or arctic wind stations.

The Challenges of Scalability and Cost

Despite the incredible progress, the industry in 2026 still faces challenges. The primary hurdle is the cost of raw materials. High-purity lithium and specialized ceramic materials are expensive. While the manufacturing processes are improving, solid-state batteries currently cost about 30 percent to 50 percent more to produce than high-end lithium-ion cells.

The industry is responding by developing more efficient supply chains. There is a massive global effort to find alternative electrolyte materials that do not rely on rare earth elements. Additionally, as production volume increases throughout 2026 and 2027, economies of scale are expected to bring prices down significantly.

Sustainable Manufacturing and Recycling

Sustainability is a major theme in 2026. The production of solid-state batteries is generally cleaner than traditional methods. Many of the toxic solvents used in liquid electrolyte production are unnecessary in solid-state plants. Furthermore, the longevity of these cells means they need to be replaced less frequently, reducing the overall environmental footprint.

Recycling processes for solid-state batteries are also being standardized. In 2026, new regulations in the European Union and North America require battery manufacturers to have a clear “cradle-to-grave” plan. Because the materials in a solid-state cell are more stable, they can be easier to disassemble and refine for reuse in new batteries.

Investment Trends in Next-Gen Energy

The financial world is pouring capital into the battery sector at unprecedented levels. In 2026, the market for solid-state technology is projected to grow at a compound annual growth rate of over 30 percent. Investors are focusing on companies that control the intellectual property for electrolytes and those that have proven they can manufacture at scale.

We are also seeing a vertical integration trend. Automotive companies are no longer just buying batteries; they are investing directly in the mining of lithium and the production of electrolytes. This secure supply chain is seen as a vital competitive advantage in the 2026 market.

Daily Information and Real-Time Developments

The landscape changes daily. As of late December 2025 and moving into early 2026, here are the latest field reports from the industry:

- Pilot Plant Commissioning: Multiple sulfide electrolyte production lines in South Korea have reached ton-level capacity this month. This marks a transition from laboratory samples to industrial-scale material supply.

- Real-World Testing: A prototype vehicle equipped with an all-solid-state pack recently completed a cross-country winter test in Northern Europe, maintaining 92 percent of its rated range in sub-zero temperatures.

- Government Subsidies: New policy frameworks in the United States and China are providing tax credits specifically for “next-generation energy storage,” which includes all-solid-state designs.

- Collaborative Alliances: BMW, Ford, and Solid Power have expanded their joint development agreement to include a new specialized facility for high-nickel cathode integration.

Conclusion and Future Outlook

As we look toward the remainder of 2026 and into 2030, the trajectory is clear. Solid-state batteries are no longer a “future technology.” They are a present-day reality that is beginning to reshape transportation, aviation, and the power grid. While we are currently in the high-end adoption phase, the lessons learned on the production lines today will pave the way for affordable, high-performance batteries for everyone.

The year 2026 will be remembered as the moment the energy transition shifted into high gear. With energy densities doubling and safety concerns diminishing, the world is finally ready to move past the limitations of the internal combustion engine and the liquid-battery era.

Sources for Further Reading

For those who wish to dive deeper into the technical and market data surrounding this revolution, the following resources provide comprehensive insights:

- Toyota Battery Technology Roadmap: https://www.toyota-europe.com/news/2023/battery-technology

- IDTechEx Research on Solid-State Batteries 2026-2036: https://www.idtechex.com/en/research-report/solid-state-batteries/1130

- QuantumScape Investor Relations and Cobra Process Updates: https://www.quantumscape.com/resources/

- Samsung SDI Global Roadmap for 2027 Mass Production: https://evtechinsider.com/samsung-sdi-to-start-mass-producing-solid-state-batteries-in-2027/

- MDPI Scientific Journal on Advances in Solid-State Lithium Batteries: https://www.mdpi.com/2313-0105/11/3/90