The year 2026 marks a historic turning point in the automotive industry. As we move deeper into this decade, the electric vehicle (EV) market has transitioned from a niche segment into the primary driver of global transportation. Central to this revolution is the rapid evolution of battery technology. For anyone following the latest trends in the automotive world, understanding the nuances of power storage is no longer optional. It is essential.

- The State of Electric Mobility in 2026

- 1. Lithium-Ion Batteries (The Industry Standard)

- 2. The Solid-State Revolution: The “Holy Grail” Arrives

- 3. Sodium-Ion Batteries: The Low-Cost Alternative

- 4. Specialized Chemistries: Lithium-Sulfur and Silicon Anodes

- 5. Battery Management Systems (BMS) and Software

- 6. Manufacturing Dominance and the Global Supply Chain

- 7. The Circular Economy: Recycling in 2026

- 8. Summary of EV Battery Types (Quick Reference)

- 9. Future Outlook: Beyond 2026

In this comprehensive guide, we will analyze the various types of EV batteries currently dominating the market in 2026. From the established lithium-ion variants to the long-awaited arrival of solid-state technology, this article provides a deep dive into the chemistry, efficiency, and economic impact of the cells that power our world.

The State of Electric Mobility in 2026

As of late 2025 and moving into 2026, the global EV battery market has surpassed a valuation of 170 billion dollars. While previous years were defined by supply chain shortages and experimental prototypes, 2026 is defined by scale and diversification. Manufacturers like CATL, BYD, and LG Energy Solution have optimized their production lines, while newcomers in Europe and North America are finally bringing domestic gigafactories online.

The primary focus for researchers this year has been three-fold: increasing energy density, reducing charging times, and eliminating reliance on rare-earth minerals like cobalt. The results of these efforts are visible in the diverse range of battery chemistries available in showrooms today.

1. Lithium-Ion Batteries (The Industry Standard)

Despite the emergence of new technologies, lithium-ion remains the backbone of the EV industry. However, the lithium-ion battery of 2026 is far more advanced than the versions seen five years ago. This category is broadly divided into two main sub-types based on their cathode chemistry: NMC and LFP.

NMC (Nickel Manganese Cobalt)

NMC batteries are the preferred choice for high-performance and long-range vehicles. In 2026, the industry has shifted toward high-nickel chemistries such as NMC 811 (8 parts nickel, 1 part manganese, 1 part cobalt).

- Energy Density: NMC cells currently offer between 250 and 300 Wh/kg at the pack level.

- Range: These batteries typically power vehicles with ranges exceeding 400 miles (640 km) on a single charge.

- 2026 Trends: The focus here is “cobalt-free” or “ultra-low cobalt” designs. Reducing cobalt not only lowers the cost but also addresses ethical concerns regarding mining practices.

LFP (Lithium Iron Phosphate)

If NMC is the king of performance, LFP is the king of the mass market. In 2026, LFP has become the standard for entry-level and mid-range EVs.

- Durability: LFP batteries are known for their exceptional cycle life, often lasting over 3,000 to 5,000 full charge cycles with minimal degradation.

- Safety: The thermal stability of LFP is significantly higher than NMC, making them virtually immune to thermal runaway or “venting with flame.”

- Economic Impact: BYD’s Blade Battery and CATL’s Shenxing fast-charging LFP cells have revolutionized this segment. In 2026, we are seeing LFP batteries that can add 400 km of range in just 10 minutes of charging.

2. The Solid-State Revolution: The “Holy Grail” Arrives

For years, solid-state batteries (SSB) were considered a distant dream. However, December 2025 and January 2026 have seen the first real-world applications of this technology in flagship luxury vehicles.

What Makes Solid-State Different?

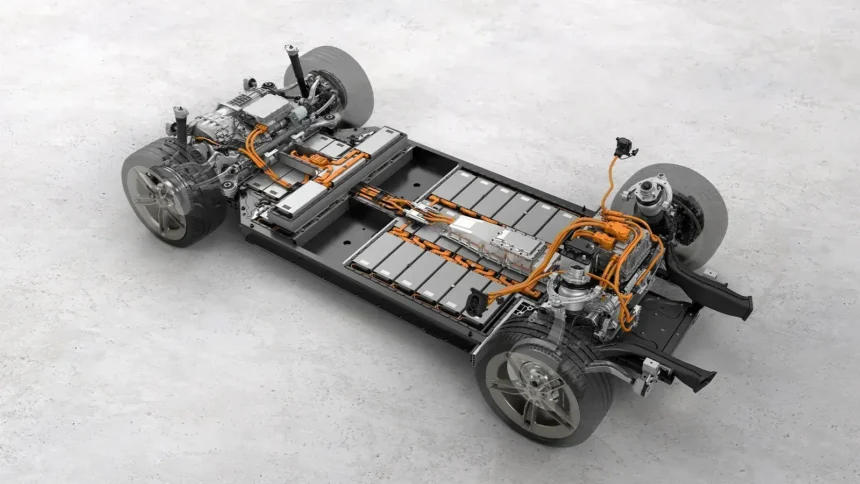

Traditional batteries use a liquid electrolyte to move ions between the anode and cathode. Solid-state batteries replace this liquid with a solid ceramic, glass, or polymer material.

- High Energy Density: By 2026, solid-state cells have reached densities of 400 to 500 Wh/kg.

- Rapid Charging: Because solid electrolytes are less prone to heat buildup, they can handle much higher current. Samsung recently announced solid-state prototypes that can fully charge in under 10 minutes.

- Market Status: While still expensive, brands like Toyota and GAC Group have begun small-batch production. These batteries are currently found in premium EVs where weight reduction is a top priority.

A significant side effect of the solid-state surge in 2026 is the impact on the commodities market. Silver has become a core raw material for certain solid-state designs, leading to record high demand for the precious metal in industrial applications.

3. Sodium-Ion Batteries: The Low-Cost Alternative

One of the most exciting developments in 2026 is the commercialization of sodium-ion technology. As lithium prices fluctuated wildly over the past few years, manufacturers looked for a more abundant alternative. Sodium, which can be derived from common sea salt, is the answer.

Key Advantages of Sodium-Ion

- Abundance: Sodium is thousands of times more abundant than lithium, making these batteries significantly cheaper to produce at scale.

- Low-Temperature Performance: Sodium-ion batteries retain up to 85 percent of their capacity at -20 degrees Celsius, solving a major pain point for EV owners in colder climates.

- Safety: They can be discharged to zero volts for shipping and storage without damaging the internal chemistry, unlike lithium-ion cells.

In 2026, we are seeing sodium-ion batteries in micro-mobility solutions like electric scooters, urban “city cars,” and stationary energy storage systems. Companies like TIAMAT in France and HiNa Battery in China are leading this transition.

4. Specialized Chemistries: Lithium-Sulfur and Silicon Anodes

Beyond the mainstream options, 2026 has introduced specialized batteries designed for specific niches such as aviation and long-haul trucking.

Lithium-Sulfur (Li-S)

Lithium-sulfur batteries are theoretically capable of five times the energy density of lithium-ion. In early 2026, they have found a home in the aerospace sector.

- Weight: Because sulfur is lightweight, these batteries are ideal for drones and electric vertical take-off and landing (eVTOL) aircraft.

- Sustainability: Sulfur is an industrial byproduct, making it environmentally friendly and inexpensive.

- Challenge: The primary hurdle in 2026 remains the cycle life, though researchers in Melbourne and Sweden have recently reported breakthroughs in stabilizing the cathode structure.

Silicon Anodes

By replacing traditional graphite anodes with silicon, manufacturers can significantly increase energy storage capacity. Tesla and Panasonic have been at the forefront of this trend in 2026, using silicon-carbon composites to boost the range of their latest models by nearly 20 percent without increasing the size of the battery pack.

5. Battery Management Systems (BMS) and Software

The hardware is only half the story. In 2026, the “Intelligence of the Battery” is just as important as the chemistry. Modern Battery Management Systems use artificial intelligence to monitor every individual cell in real-time.

- Predictive Maintenance: AI algorithms can now predict a cell failure weeks before it happens, allowing for proactive servicing.

- Thermal Management: Advanced liquid-cooling and phase-change materials ensure that batteries operate at their “sweet spot” temperature, extending the life of the vehicle to 20 years or more.

- Vehicle-to-Grid (V2G): In 2026, many EVs act as mobile power banks. The BMS allows the car to sell electricity back to the grid during peak hours, providing a new stream of value for car owners.

6. Manufacturing Dominance and the Global Supply Chain

The geopolitical landscape of battery production in 2026 is fascinating. While China continues to lead in total output, the “Regionalization of Supply” is the main trend this year.

China (The Global Leader)

China is projected to drive 71 percent of global battery manufacturing investment through 2026. Companies like CATL are not just manufacturers but global energy titans, supplying batteries for one out of every three EVs on the road.

Europe (The Sustainability Hub)

Europe has focused on a “Circular Economy” approach. The PowerCo gigafactory in Salzgitter, Germany, which began production in late 2025, is a model for the future. It operates entirely on renewable energy and features integrated recycling facilities on-site.

North America (The Resiliency Drive)

Supported by massive federal grants and tax incentives, the United States and Canada have established a “Battery Belt” in the Midwest and South. The focus here is on domestic sourcing of lithium and nickel to reduce dependency on overseas imports.

7. The Circular Economy: Recycling in 2026

As the first generation of mass-market EVs reaches the end of its life, battery recycling has become a multi-billion dollar industry. In 2026, we no longer view old batteries as waste but as “Urban Mines.”

- Hydrometallurgy: This process uses aqueous solutions to recover up to 98 percent of metals like lithium, cobalt, and nickel with a very low carbon footprint.

- Black Mass Processing: Specialized facilities now process “black mass” (the crushed remains of old batteries) to extract high-purity materials that go directly back into the production of new cells.

- Second-Life Applications: Batteries that are no longer suitable for cars (retaining 70 to 80 percent capacity) are being repurposed for stationary grid storage, helping to stabilize renewable energy from wind and solar farms.

8. Summary of EV Battery Types (Quick Reference)

| Battery Type | Key Advantage | Best For | 2026 Status |

| NMC | High Energy Density | Long-range & Luxury EVs | Transitioning to low-cobalt |

| LFP | Safety & Longevity | Mass-market & City cars | Dominating the budget segment |

| Solid-State | Fastest Charging | Performance & High-end | Entering low-volume production |

| Sodium-Ion | Extremely Low Cost | Micro-mobility & Storage | Rapidly scaling in 2026 |

| Li-Sulfur | Ultra-lightweight | Aerospace & Drones | Emerging in specialized fields |

9. Future Outlook: Beyond 2026

Looking past 2026, the trajectory of EV batteries is clear: they will become cheaper, safer, and more sustainable. We are already seeing research into “Graphene” and “Air-form” batteries that could potentially double the range again by 2030.

The investment opportunities in this sector are vast. From mining and chemical processing to AI-driven software and recycling infrastructure, the battery ecosystem is the engine of the modern economy.